Explore our extensive product range below.

Studbolts & Nuts

Finished studbolts and studbolt assemblies are available from stock in both Imperial and Metric threads and in a range of different finishes. Our studbolts are widely used in the Petrochemical industry and are covered in the ASTM standards A193 for high temperature or high pressure service, and A320 for low temperature service. A selection of the most commonly used studbolt materials are listed in the table below.

Coating Systems

Electroplated Coatings

A thin electroplating coating layer can be used to improve the corrosion resistance of most bolting components under general indoor usage conditions. It can also be combined with an appropriate topcoat (e.g. fluoropolymers) for outdoor usage or even severe environmental conditions.

« Zinc Plating as per ASTM B633 or ASTM F1941

« Cadmium Plating as per ASTM B766 or ASTM F1941

« Zinc-Nickel Plating as per ASTM B841 or ASTM F1941

Fluoropolymer Coatings

As a Whitford Quality Approved Coator, we proualy endorse Xylan® fluoropolymer coatings. Yylan® coatings are widely used in the petrochomical industry to provide improved resistance to chemical attack, abrasion and corrosion, allowing them to be used in severe environmental conditions.

+ Whitford xylan® 1014

+ Whitford Xslan® 1070

+ Whitford xylan 1424

Ceramic-Metal Coatings

Xylar® 2 ceramic-metal costings are used to provide corrosion resistance even in high temporature envionments, where many other coating solutions fail.

+ Whitford xylar 2

Galvanized Coatings

A thick galvanized coating layer can be used to improve the corrosion resistance of most bolting components under general outdoor usage conditions.

+ Hot bip Galvanizodas por ASTM A153, ASTM F2329, BS 7371-6,1S0

1461 or 8010684

+ Mechanically Deposited Zinc as per ASTM B695,

Zinc-Aluminium Coatings

As a NOF Metal Coatings licensee, we proudly endorse DACROMET® and GEOMET® zinc-aluminium coatings. A thin zinc-aluminium layer can be used to improve the corrosion resistance of all bolting components under indoor, outdoor and offshore usage conditions. The zinc aluminium coating process is free from risk of hydrogen embrittlement, allowing it to be used even for very high strength bolting materials.

+ NOF DACROMET® as per ASTM F136 0-150 10683,

+ NOF GEOMET® as per ASTM F1136 or ISO 10683

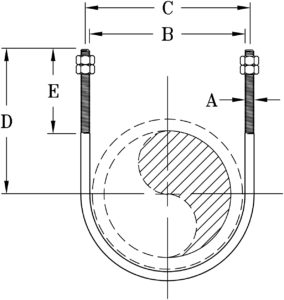

Types of U-Bolts

MATERIAL: Carbon steel

FINISH: Black. Galvanized upon request.

ORDERING: Specify figure number, pipe size, description, and finish, if other than black.

NOTE:

• U-bolts are furnished with four hexagon nuts or are furnished with two hexagon nuts.

• Special U-bolts with longer tangents and threads and special materials can be furnished as specified.

MATERIAL: Carbon steel

FINISH: Black. Galvanized upon request.

ORDERING: Specify figure number, pipe size, description, and finish, if other than black.

NOTE:

• U-bolts are furnished with four hexagon nuts or are furnished with two hexagon nuts.

• Special U-bolts with longer tangents and threads and special materials can be furnished as specified.

Contact Us Today

Your Leading Stockist of Pipe, Tubes, Fittings, Flanges and Specialist Forgings in Duplex, Chrome Alloy and Nickel Alloys