Supports With No Field Welding

Explore our extensive product range below.

Specifications

Pipe shoes and pipe guides are available in a variety of designs. Slide plates may be included on the pipe shoes for smooth sliding. Custom pipe shoes and anchors can be designed to meet your specific design requirements.

Scroll right for more >>

GENERAL DIMENSIONS & SPECIFICATIONS

PIPE GUIDE

TYPE OF CRADLE SUPPORT

SHOE CLAMP

TYPES OF SADDLES

PIPE GUIDE

FIG. 6: CYLINDER PIPE GUIDE (SPIDER GUIDE)

APPLICATION: Design for use on pipe lines containing expansion joints or other critical components where lateral pipe movement needs to be controlled. More than one spider guide should be used adjacent to avoid a fulcrum, imposing lateral deflection on critical components (expansion joints). The guide can be furnished with split sleeve or solid, and they can be modified to suit.

FINISH: Black or hot dipped galvanized.

ORDERING: Specify figure number, pipe size, description, and finish. Please specify long or short design when ordering.

TYPE OF CRADLE SUPPORT

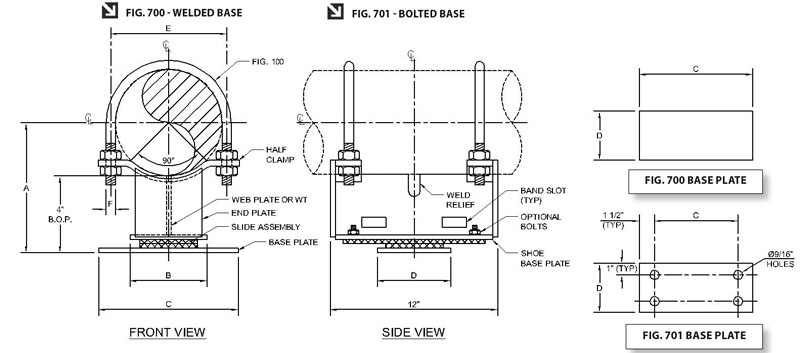

FIG. 700: U-BOLT CRADLE SUPPORT WITH BONDED/BOLTED SLIDE PLATE

MATERIAL: Mild Steel and Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, B, C, D, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500°F specify bolted construction.

NOTE:

• Optional bolted base plate, specify Fig. 701

• End Plates provided for pipe sizes 3″ & above

• For upper graphite slide material to be of bolted design, specify Fig. 700 base plate or Fig. 701 base plate (see below).

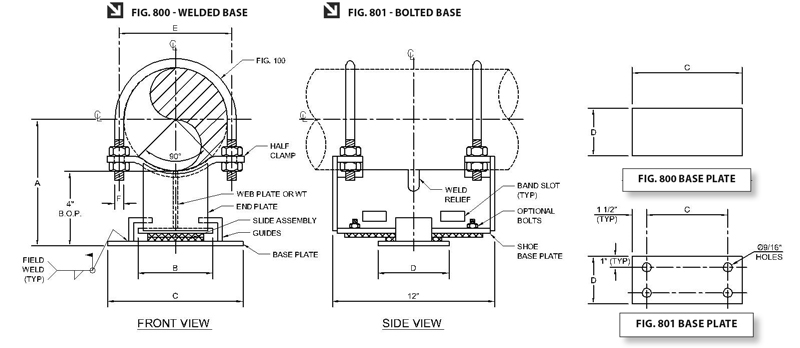

FIG. 800: U-BOLT CRADLE SUPPORT WITH GUIDE & SLIDE PLATE

MATERIAL: Mild Steel and Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, B, C, D, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500°F specify bolted construction.

NOTE:

• Optional bolted base plate, specify Fig. 801.

• For upper graphite slide material to be of bolted design, specify Fig. 800 base plate or Fig. 801 base plate (see below).

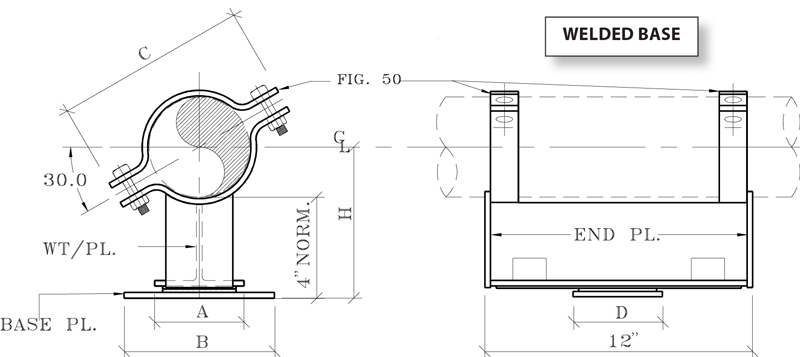

FIG. 900: BOLT CRADLE SUPPORT WITH BONDED/BOLTED SLIDE PLATE (WELDED BASE)

MATERIAL: Mild Steel and Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, B, C, D, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500°F specify bolted construction.

NOTE: End Plates provided for pipe sizes 3″ & above

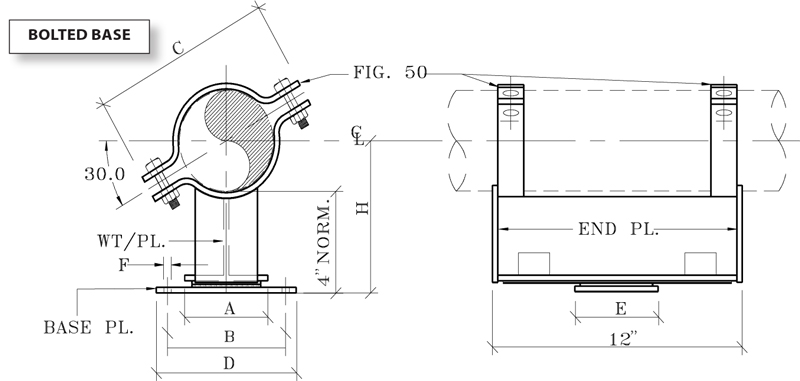

FIG. 1000: BOLT CRADLE SUPPORT WITH BONDED/BOLTED SLIDE PLATE (BOLTED BASE)

MATERIAL: Mild Steel and Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, B, C, D, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500°F specify bolted construction.

NOTE: End Plates provided for pipe sizes 3″ & above

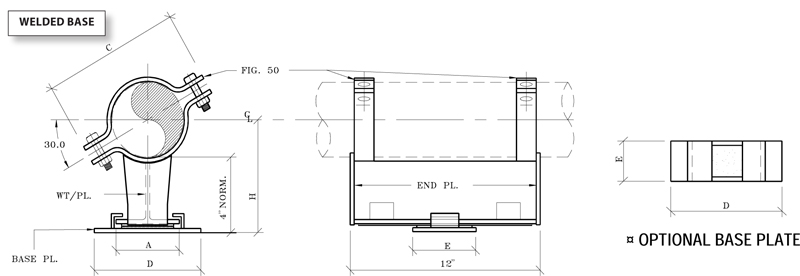

FIG. 1100: BOLT CRADLE SUPPORT WITH GUIDE & SLIDE PLATE (WELDED BASE)

MATERIAL: Mild Steel and Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, C, D, E, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500 °F specify bolted construction.

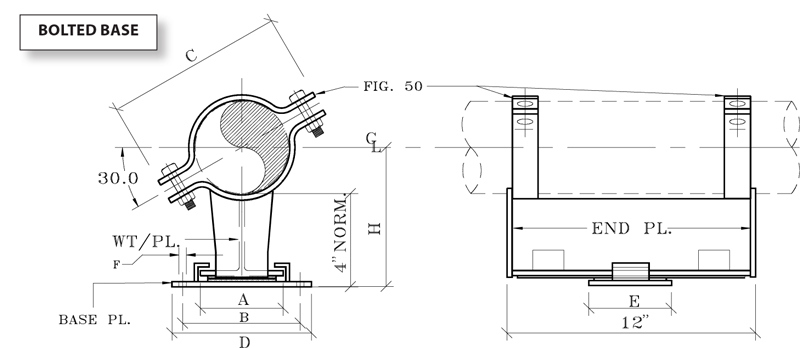

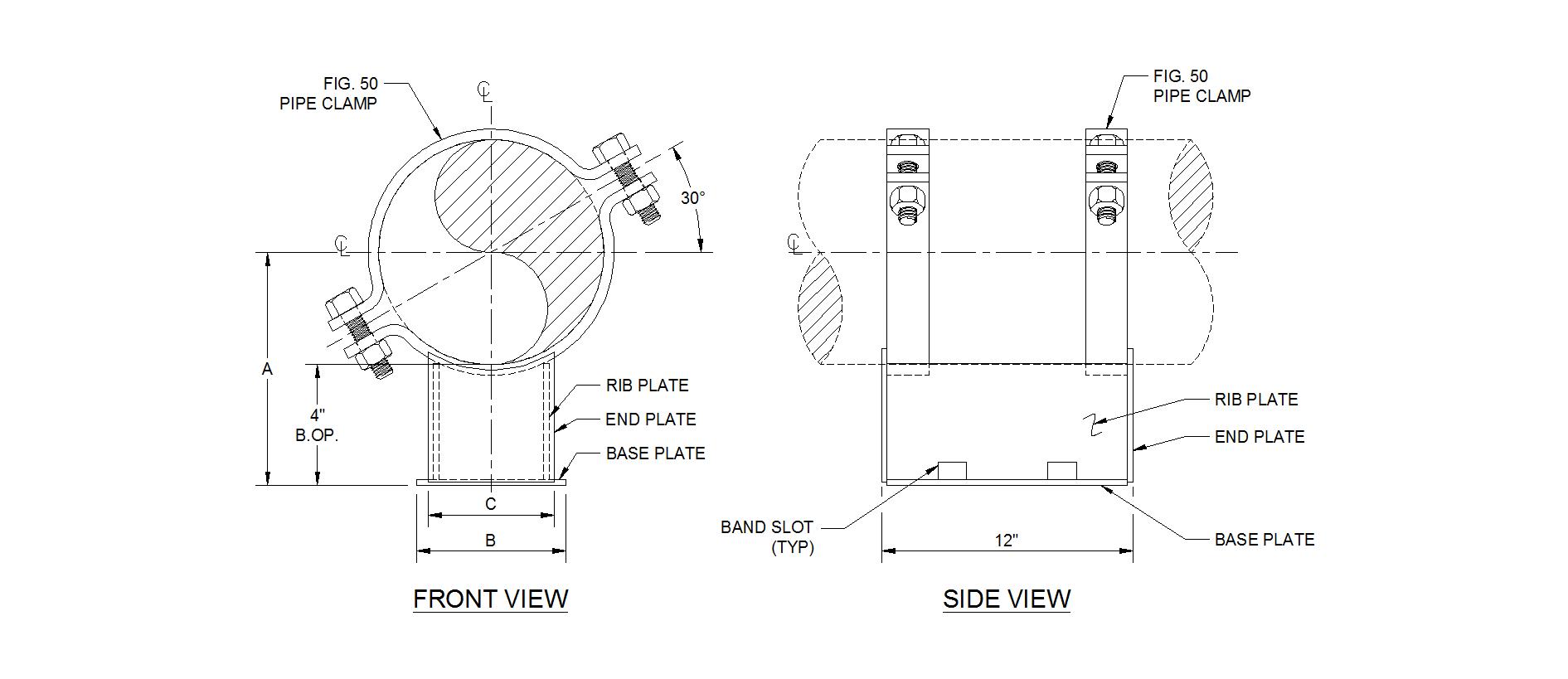

FIG. 1200: BOLT CRADLE SUPPORT WITH GUIDE & SLIDE PLATE (BOLTED BASE)

MATERIAL: Mild Steel and Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, B, C, D, and the slide plate material (PTFE, 25% glass filled or graphite) available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, finish and slide plate material.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

BONDING: Graphite slide plates are usually bonded. For high temperature service above 500°F specify bolted construction.

SHOE CLAMP

FIG. 1400: PIPE SHOE CLAMP

MATERIAL: Carbon steel

FINISH: Painted or hot dipped galvanized.

OPTIONS: Modifications in the dimensions A, B, C, and L are available upon request.

ORDERING: Specify figure number, pipe size, description, type, quantity, and finish.

ALLOWABLE LOADS: The allowable vertical loads depend upon the pipe pressure and wall thickness.

NOTE: Special two-way, three-way, and four-way versions can be made available upon request.

TYPES OF SADDLES

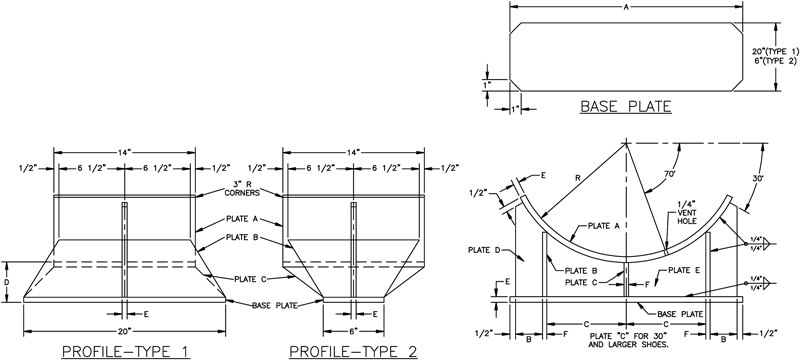

FIG. 2000: HEAVY DUTY PIPE SADDLES

ORDERING: Specify figure number, pipe size and description.

NOTE:

- Tolerances: R=1%-0

Other Dimension – 1/16, Except Plate Thickness – 1/32 Angle – 1 1/4 Deg. - Full Encirclement Saddle Plates shall be used on all cross country pipelines, on Grade X-46 or higher strength pipe, and on all station pipework designed to operate at or in excess of 90% of min. specified yield strength. Segmental Saddle Plates shall be used on station pipe work designed to operate at less than 50% of min. yield strength.

- For maximum spans of pipelines using saddles use Standard Engineering Practice.

- Pipe Support of sleeper under the saddle shall be designed to accommodate full axial movement of the pipeline and saddle.

- Vent hole 1/4 to be drilled in each segment of saddle.

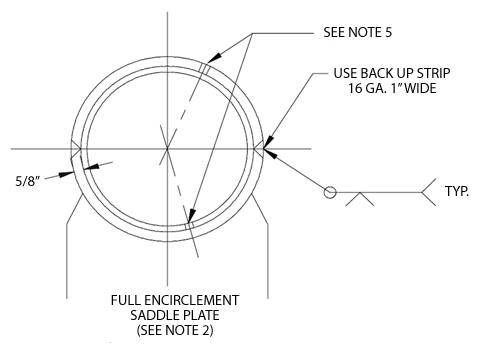

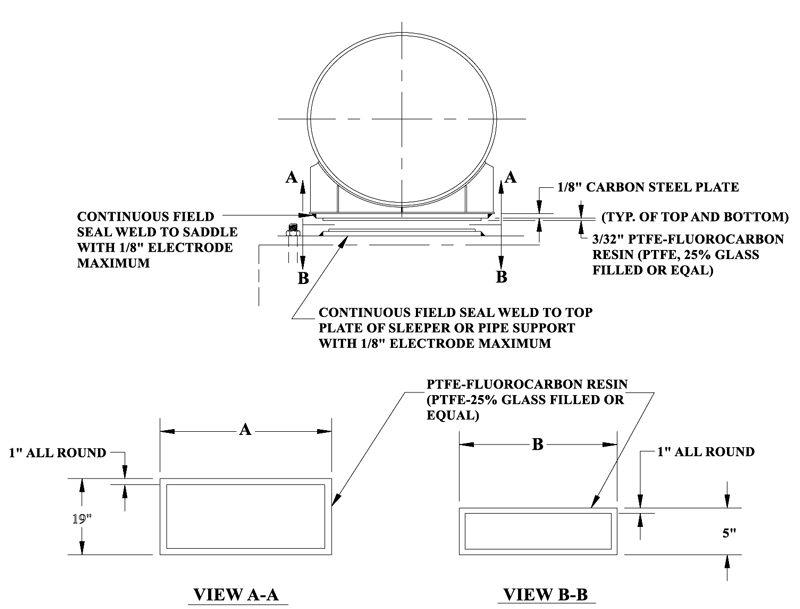

FIG. 2000-S: SLIDE BEARING DETAILS FOR HEAVY DUTY PIPE SADDLES

NOTE:

• PTFE, 25% glass filled, properties shall be as follows:

* Filler – 25% Glass Fiber

* Specific Gravity – 2.22 (Nominal)

* Tensile Strength – 2,100 psi. Minimum and to ASTM D 1457.

* Compressive Strength – 1870 psi. Minimum at 0.2% Deformation and to ASTM D695.

• PTFE 25% glass filled, pad shall be chemically etched and bonded to the Carbon Steel Plate using a hot setting epoxy resin adhesive.

• Maximum Allowable Pipe Operating Temperature 325°F.

• For 20″ – 60″ Pipe Saddle Details refer to Fig. 2000.

• Maximum Axial Movement on support is 6″ (3″ each direction.) If Axial movement is in excess of 12″ the base width shall be increased accordingly.

ORDERING: Specify figure number, pipe size, description, and slide plate material.

Contact Us Today

Your Leading Stockist of Pipe, Tubes, Fittings, Flanges and Specialist Forgings in Duplex, Chrome Alloy and Nickel Alloys